The Asian laser market is closely linked to China’s high production capacity. Despite slowing economic growth last year, China remains the dominant market for growth in Asian laser products. In the next five to ten years, China’s laser and optoelectronics industry is expected to grow at an annual rate of 10-15%. During this period, China’s laser industry will also make greater progress. Chinese laser companies are increasingly competing with Western producers, and other advanced national manufacturers must respond to this trend and adapt to the pace of China’s economy.

In fact, almost all of the Asian laser pointer applications are growing, and even part of the microelectronics industry will be almost completely locked in Asia. Based on the continuous expansion of new applications, the growth of the core market is far from over. In some areas, the level of specialization in individual industrial sectors is increasing.

Machinery manufacturing

In the machinery industry, China’s demand for laser manufacturing products is the primary driver of growth. At present, the human-intensive manufacturing industry to a higher degree of automation has undergone a significant change, which improves the high-quality machinery and automated process technology needs.

Over the past year, 1-2kW fiber lasers in China’s demand is still high. However, at present, cutting applications are also increasingly inclined to higher power. In the lower and medium power range, more and more laser light sources are now available from local blue laser pointer manufacturers, many of which have also introduced power up to 1kW rack-mounted lasers. This year, the demand for cutting-type lasers has turned to 3-4kW, the future will advance towards 6-8kW.

However, the first 10-12kW power laser system has also been delivered. Japanese cutting machine manufacturers to its domestic market mainly to provide 2-4kW output range of machines, and more than 6kW large format laser cutting system is exported to Europe and the United States.

Automobile industry

The growth of the Asian automotive industry is mainly from China and India. In 2016, only China produced 28.1 million cars. In the process, China has further consolidated its position as the world’s largest auto market, with the largest increase in passenger cars reaching 16% year-on-year. While India’s overall purchasing power is low, the market growth rate is not as fast as China, India in 2016 car production of 4.5 million, the world’s fifth. In addition, South Korea after 11 years missed the world’s top five car manufacturers last year, vehicle production fell 7%, ranked sixth in the world. Nevertheless, South Korean first-line carmakers still expand their market share in Asia, which accounts for 62% of Korea’s total car exports. While Japan had to face another round of sluggish production.

Now the application of lasers in China is also mature, especially in the “white body” part, while Sino-foreign joint venture car manufacturers also help speed up the introduction of green laser light technology. In the “white body”, the Japanese more and more traditional technology has also been replaced by laser processing. In addition, laser processing is expected in the application of aluminum welding will also be a significant increase.

Laser cutting, welding and marking applications in the automotive body manufacturing applications more and more widely, the trend of automotive electronics has gradually begun to dominate the laser application in the automotive industry development speed. Battery manufacturers to become an important consumer of laser light, last year’s investment has increased significantly. These lasers cover a wide range of applications including batteries and their enclosures, modular designs and their packaging. 1μm lasers are ideal for processing materials such as aluminum and copper. In addition, a highly dynamic galvanometer scanning solution can increase the productivity of almost all applications in the battery industry.

For primary manufacturers, the application of fuel injection systems for welding and balloon cutting is becoming more and more important. Asian car manufacturers are also increasingly interested in the latest applications such as glass cutting.

Medical engineering industry

Many areas of Asia have a strong demand for medical devices and implants, coupled with government support, for the 500mw green laser application to create a lot of space.

In medical device engineering, often from UV to mid-infrared range of different laser technology. The use of the correct wavelength for a given material ensures effective operation and good productivity characteristics. Depending on the accuracy requirements, a short pulse nanosecond laser or a (ultrashort pulse) picosecond laser may be used. The ultrashort pulse reduces the size of the heating zone and combines the cold working process to become the most accurate technology. The method is used in demanding applications such as stand production.

In the field of stents, often faced with various national price laws and regulations constraints, such as in India, the government set the price of stents to standardize the cost of medical engineering products. As a result, suppliers in the United States and elsewhere have withdrawn from the market in India. For laser manufacturers, this brings both opportunities and uncertainties.

In addition, laser marking or lettering function is also being further improved. By changing the color of the material, combined with metal annealing, carbonization or plastic foaming and other means, can produce non-corrosive mark, without the use of burrs to modify the surface of the treatment, without the introduction of additional materials. There are few technical limitations in the form and content of 50mw green laser marking, whether it involves implants or the marking of medical equipment. Even if only fine marks with characters of several μm height are possible.

Other industries

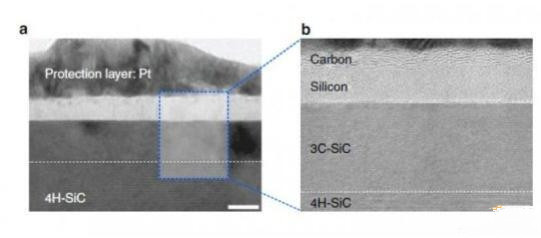

As mentioned at the outset, markets in other Asian markets, such as the textile and packaging industry, the semiconductor and microelectronics industries, or solar technology, continue to show positive growth momentum. The importance of laser processing coincides with the manufacturer’s desire to produce a smaller, more powerful, more reliable device.

(8)