Laser cooling refers to the use of a beam or beam of specific laser irradiation material, the interaction between the laser and the material, the temperature of the object becomes low. However, it can be seen from the daily life experience, the object can absorb light energy and heat, such as we all love the sun on the beach, in the summer sun on the road to a barefoot and so on. Compared with the sun, laser power density is higher, high power laser can even melting the material, so you can use laser machining, cutting, manufacturing laser weapons and so on.

If someone says that the laser can be used to cool, maybe people will feel a little counterintuitive. But in fact, scientists have not only realized the cooling of rare atomic gas by laser, but also realized the solid material refrigeration by laser in recent years. So how does the laser cool the material? To explain this problem, we need to understand what temperature is. In a simple way, heat is the manifestation of the atomic motion in the material, and the degree of heat and cold represents the intensity of the atomic motion of the material. Take water molecules for example: the higher the temperature, the faster the movement of water molecules, the greater the magnitude of free movement. When the water temperature is higher than the boiling point, the water will boil, a large number of water molecules out of the water, gas and water; the lower the temperature is, the slower the molecular motion, the motion amplitude is small, when the water temperature is below the freezing point of water, ice, can only be around the center position of vibration. Under the concept of quantum mechanics, the energy of this thermal vibration is quantized into phonons.

Laser cooling of solids, also known as Optical Refrigeration, was first proposed by German physicist Peter Pringsheim back in 1929. The basic principle is that when a laser-cooled material is irradiated with monochromatic light of a specific wavelength, the material absorbs low-energy red laser photons (long-wavelength photons) and simultaneously emits the same number of high-energy photons by spontaneous radiation (Short wavelength photons) – this process is called upconversion fluorescence or anti-Stokes fluorescence. According to the law of conservation of energy, the emitted high-energy photons need to take away a part of the energy from the material, which can be the thermal vibration (phonon) of the material. When a phonon in a substance is absorbed and phonon energy is taken away by photons emitted and there is no other additional heating mechanism, the temperature of the substance drops. After this theory was put forward, there has been a historical controversy over whether this process violates the second law of thermodynamics.

Eventually, Landau gave the definition of optical radiation entropy in 1946, and solved thermodynamically the physics of photoluminescence mechanism. Optical radiation entropy represents the degree of order of the radiation photons. The more monochromatic the radiation photons, the narrower the frequency distribution is. Therefore, the radiation entropy is smaller. On the contrary, the wider the radiation spectrum, the greater the radiation entropy. According to the second law of thermodynamics, if the temperature of a substance is to be decreased, the entropy of the substance needs to be reduced. In the process of laser cooling, the low entropy laser works on the material and changes into a high entropy spontaneous emission photon so as to satisfy the total The entropy of the system increases this basic law.

This principle was first used for cooling atoms and thin gas, when irradiated with a green laser pointer beam energy is slightly less than that of a gas atom atom transition energy required (e.g. rubidium gas) when the velocity of atomic motion and the opposite direction of the laser atom than the other direction to feel the energy of the laser will be higher, therefore these atoms the scattered photons and high energy absorption of low-energy laser photons, which is widely known as the Doppler effect. In this process, the scattered photons take away the excess energy so that the velocity of the atoms in this direction decreases, so that the temperature of the atomic gas can be reduced to very close to the absolute zero degree. The laser cooling of atomic gas is carried out at extremely low temperature of Na Kevin (nK).

In fact, the cooled material can be a single atom or molecule, or a solid composed of a large number of atoms, including short-range ordered glass (rare earth ion doping), and long-range ordered semiconductors (without intentional doping). Laser cooling of solid is very similar with the atomic laser cooling, the fundamental difference is that between the solid in a large number of atoms interact to form atomic chain, atoms are fixed in the crystal lattice, photon absorption kinetic energy is no longer isolated atom, but a large number of atomic collective vibration. In the form of lattice vibration (phonon), thermal energy can provide additional energy and momentum needed for fluorescence upconversion. Compared with laser cooling atoms, the conditions of laser cooling solid are more stringent: the external quantum efficiency of upconversion fluorescence is close to 100%.

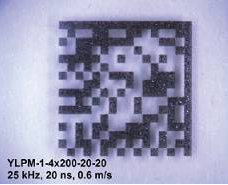

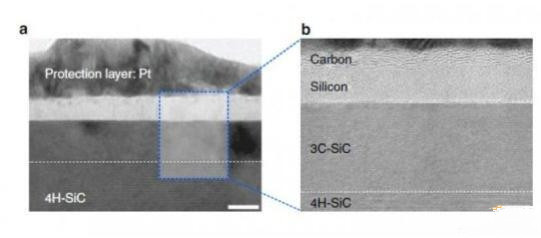

Solid laser cooling recent breakthrough in 2013, research group for the first time that the burning laser pointer can make the semiconductor cooling from room temperature to -20 degrees, the mechanism of laser cooling in different rare earth metal doped glass cooling mechanism before, the first use of free electronic band in the laser cooling. In addition, compared with rare earth materials, semiconductor materials are easier to be compatible and integrated with existing industrial systems, and lower limit temperatures can be achieved theoretically.

(5)